World’s First High-Efficiency Lithium-Ion Battery Recycling Plant Using Emulsion Flow Technology Now Operational

Emulsion Flow Technologies Ltd. (Address: Tokai-mura, Ibaraki; President: Hiroshi Suzuki; hereinafter referred to as EFT) has commenced operations of the world’s first small-scale demonstration plant utilizing the Emulsion Flow technology for efficient recycling of retired lithium-ion batteries (referred to as LIBs) from electric vehicles and electronic devices. Starting in June 2024, EFT will also launch the “EFT Foundry,” a service providing samples for recycled battery development.

1. Background

The rapid spread of electric vehicles in the automotive industry and the increasing demand for batteries in ICT devices has made LIB recycling an urgent issue. Companies worldwide are actively developing recycling technologies. However, the limited availability of old LIBs poses a challenge in acquiring sufficient quantities for development. Furthermore, the material (Black Mass or BM), rich in rare metals, left after crushing old LIBs, varies greatly depending on the battery type and processing conditions. This necessitates customized recycling processes tailored to the quality of the raw materials. Large-scale plant processing involves significant costs and environmental considerations.

EFT, a startup leveraging the innovative solvent extraction “Emulsion Flow” technology developed by the Japan Atomic Energy Agency, offers optimal recycling processes based on accumulated process data. EFT proposes appropriate processes for customer-provided BM and evaluates the recycling materials on the order of tens of kilograms to optimize raw material quality and recycling costs for recycled LIBs.

2. Features of the Emulsion Flow Small-Scale Demonstration Plant

The newly operational small-scale demonstration plant employing Emulsion Flow technology can produce recycled materials such as cobalt sulfate, nickel sulfate, lithium carbonate, and lithium hydroxide for battery development. The plant processes approximately 2 kg to 5 kg of BM per hour and has successfully operated continuously for over 30 hours, processing around 800 to 1000 liters of acid leachate from 60kg to 80 kg of BM. This process achieves high purity levels of 99% to 99.96% in the recycled materials, making them suitable for LIB recycling.

Figure 1. Emulsion Flow Small-Scale Demonstration Plant

Figure2. Recycled materials: cobalt sulfate, Nickel sulfate and Lithium carbonate (from the left)

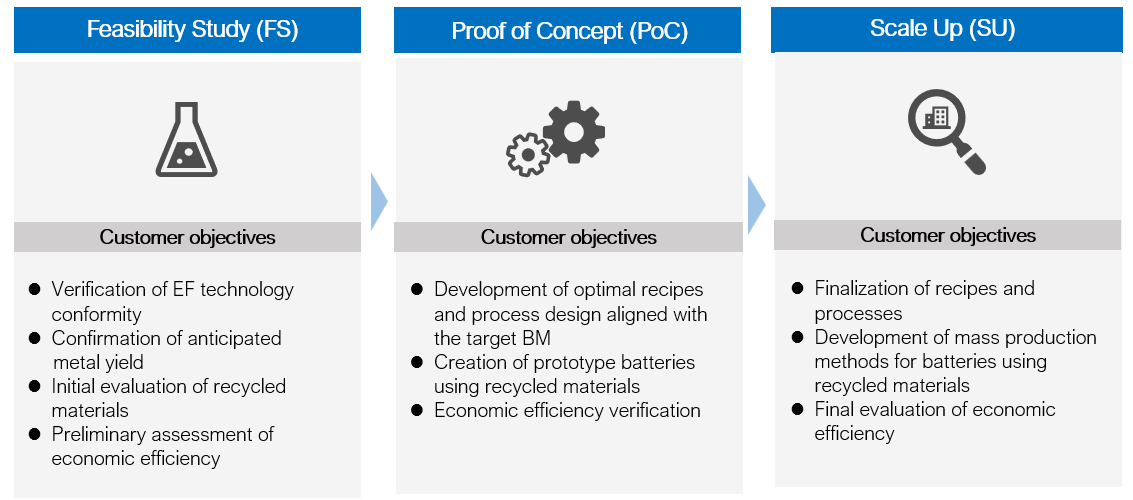

3. About EFT Foundry

A “foundry” generally refers to a contract development service. EFT’s Foundry offers comprehensive support, from custom orders for LIB recycling plant construction projects to engineering and operation, even for customers with limited BM procurement. EFT develops extraction processes to meet the required recycled material quality for any type of customer-provided BM and supplies recycled materials at pilot to commercial levels. This allows customers to secure recycled materials meeting their specifications without needing significant upfront investment in assets, facilitating efficient raw material procurement and the development of appropriately sized LIB recycling plants based on commercial-level demonstration results.

Figure 3. Foundry Service Menu

4. Future Scenario

By 2026, EFT plans to operate a commercial-scale recycling plant in Japan, enabling the provision of samples on the order of hundreds of tons necessary for mass production development of recycled LIBs through this contract development service.

About EFT

EFT, established in April 2021, is a startup leveraging the “Emulsion Flow” solvent extraction technology developed by the Japan Atomic Energy Agency. This innovative technology enables low-cost, high-efficiency, and high-purity element separation compared to conventional solvent extraction techniques, addressing social issues surrounding rare metals. The resource circulation business aims to establish a technology for low-cost, environmentally friendly, high-purity recovery of rare metals such as cobalt, nickel, and lithium from discarded LIBs. The recovered rare metals are directly reused in high-tech industries, promoting “horizontal recycling.”

Company Information:

- Name: Emulsion Flow Technologies Ltd.

- Head Office: 7-5 Shirakata, Tokai-mura, Naka, Ibaraki Prefecture, Japan

- Representative: Dr. Hiroshi Suzuki, President CEO

- Capital: JPY 1,585 billion (including capital reserves)

- Established: April 5, 2021

- Website: https://emulsion-flow.tech/en

About Emulsion Flow Technologies (EFT)

Solvent extraction is a method of separating and purifying substances by utilizing the distribution of substances between immiscible liquid phases. Traditional solvent extraction requires three steps: mixing, settling, and separating. EFT simplifies this process by simultaneously performing these steps through simple liquid transfer and agitation. Compared to conventional mixer-settlers, EFT achieves 4 to 10 times the production capacity, reduces size by over 75%, and lowers running costs. It allows flexible plant design and high scalability through a numbering-up approach. The multi-stage Emulsion Flow system enables continuous processing with high purity levels exceeding 99.99 %, making it a cost-effective and efficient method for high-purity rare metal refining. Its superior oil-water separation capability prevents oil contamination in the aqueous phase, reduces organic solvent loss, and ensures clean wastewater. EFT also offers exceptionally high concentration performance, achieving over tenfold concentration simply by adjusting the OA ratio (aqueous to organic phase flow ratio), making it an efficient solution under challenging conditions where conventional techniques fall short.

Glossary:

- 1. Black Mass (Battery Material): Material containing rare metals used in LIBs.

- 2. Japan Atomic Energy Agency (JAEA): a Japanese organization dedicated to nuclear research and development.

- 3. Mixer-Settler: Equipment for solvent extraction that separates two liquids by gravity; typically large and requires significant investment for LIB recycling.

Contact for Service Inquiries:

- Website Inquiry Form: https//www.emulsion-flow.tech/contact

- Attention to: Hashimoto (Ms)