Accelerate the

realization of a society that

will continue to use ground resources forever

The three promises to be realized by Emulsion Flow Technologies

To realize the promises

of Emulsion Flow Technologies

- Start up operation of EF plants

equipped with Emulsion Flow

Technology

for all resource recycling

processes around the world. - Undertake our initiatives as a rare

metal manufacturer to operate EF

plants to promote resource recycling

in small-scale regional markets.

Horizontal recycling and

perpetual circulation will be

realized with every EF plant

to

start operation, which will

accelerate our steps to achieve a

truly sustainable future.

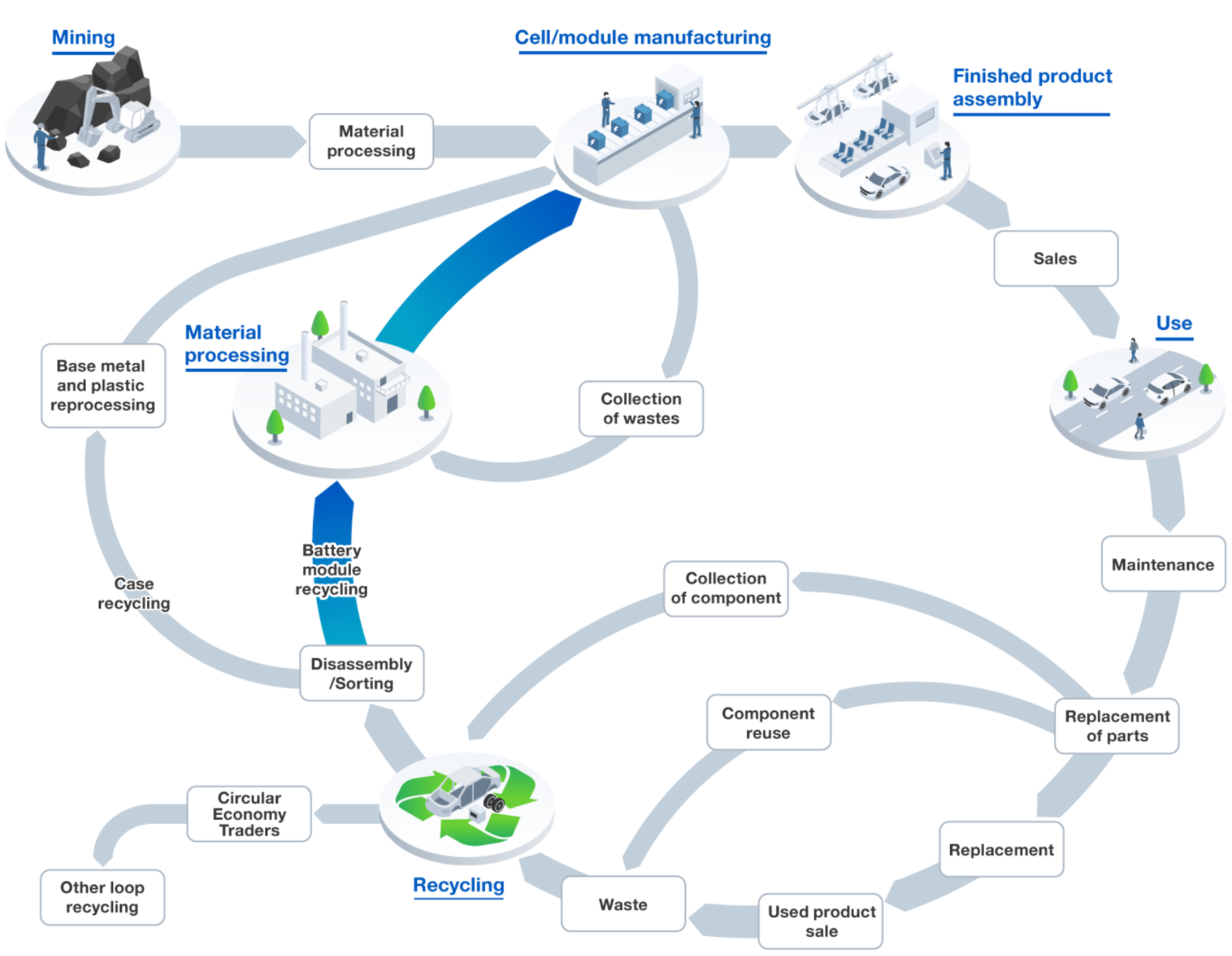

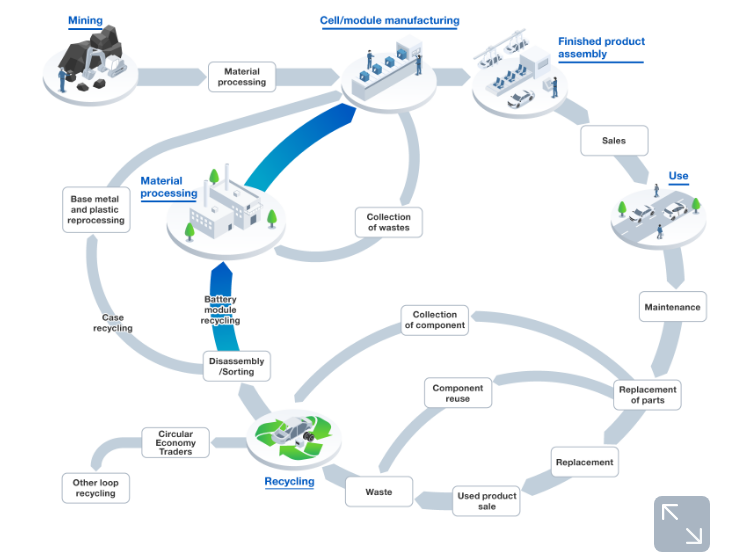

Outline of the circular economy envisioned

There are no conventional technologies to produce rare metals in the quality sufficient to recycle to a module production level from raw materials collected through dismantling and sorting. We, EFT, have developed the world’s first solvent extraction technology that enables highly efficient and highly pure rare metal recycling. We enable “horizontal recycling” for resource circulation that reuses the used materials as raw materials for product production as well as “perpetual circulation” that does not rely on underground resources.

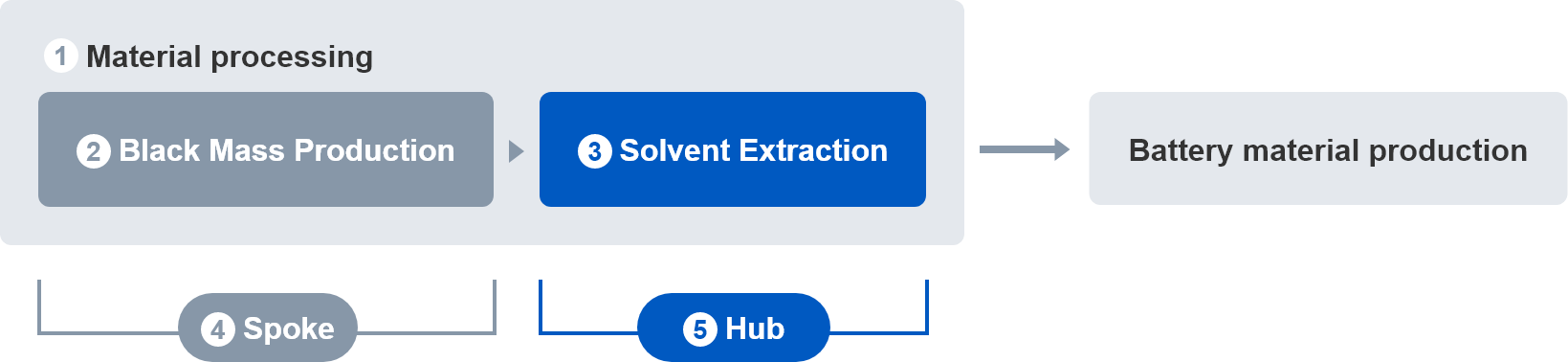

Material Processing: Solvent Extraction Process

Material Processing: Solvent Extraction Process

- 1Material

processing - The material processing process begins with the production of black mass, which is the raw material for material processing, as well as production of rare metals through the solvent extraction process and providing them as raw materials for manufacturing cells and modules.

- 2Black Mass

Production - After dismantling and sorting finished products collected through process waste and recycling, the finished products are discharged, dried, crushed, and pulverized to produce concentrated powder (black mass) containing rare metals.

- 3Solvent

Extraction - Solvent extraction is the central process in material processing for rare metal recycling. With the conventional process, products that were collected as waste were used as materials for roadbeds and so on and were never reused as products. This was due to the lack of highly efficient material processing methods. EFT has developed the world’s first solvent extraction technology that realizes highly efficient and highly pure material processing. By developing plant equipment with the technology that can handle mass production of battery-grade quality rare metals with 10 times the productivity of conventional products, we are able to supply quality materials that can be used in modules from finished products used around the world.

- 4Spoke

- Spokes are distributed bases in the spoke-and-hub system. Batteries for EV vehicles weigh 500 kg each, and the waste from finished products is collected all over the country. Transportation efficiency is improved by turning it into black mass at the places where the waste is collected.

- 5Hub

- A hub is a centralized base in the spoke-and-hub system. Since the solvent extraction process can be performed continuously around the clock, the material processing efficiency is increased by transporting the black mass and collecting it at the hub for solvent extraction. EFT manufactures and develops plants that operate at a central hub function. In addition, we provide raw materials to cell and module manufacturers with the services for dissolution and impurity removal processes as the pre-processes of solvent extraction, as well as crystallization processes as the post-processes.