Emulsion Flow, an innovative solvent

extraction technology that implements

horizontal recycling

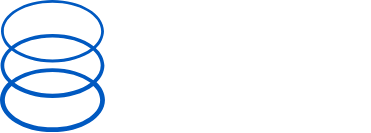

Solvent extraction is one of the methods for separating and purifying substances. It is a technique for selectively extracting only the target components by utilizing the distribution of substances between immiscible liquid phases.

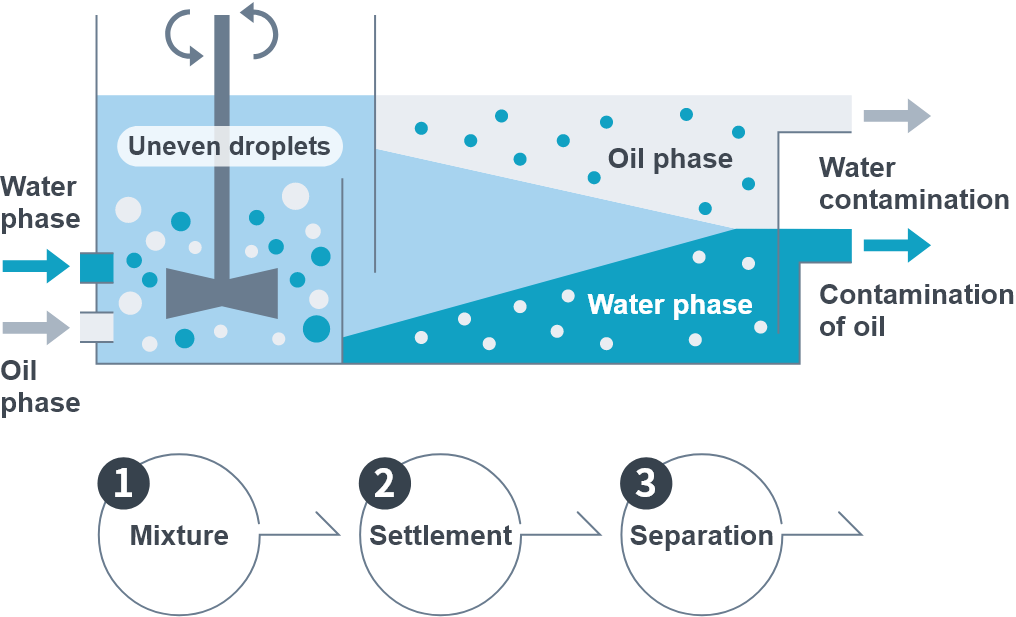

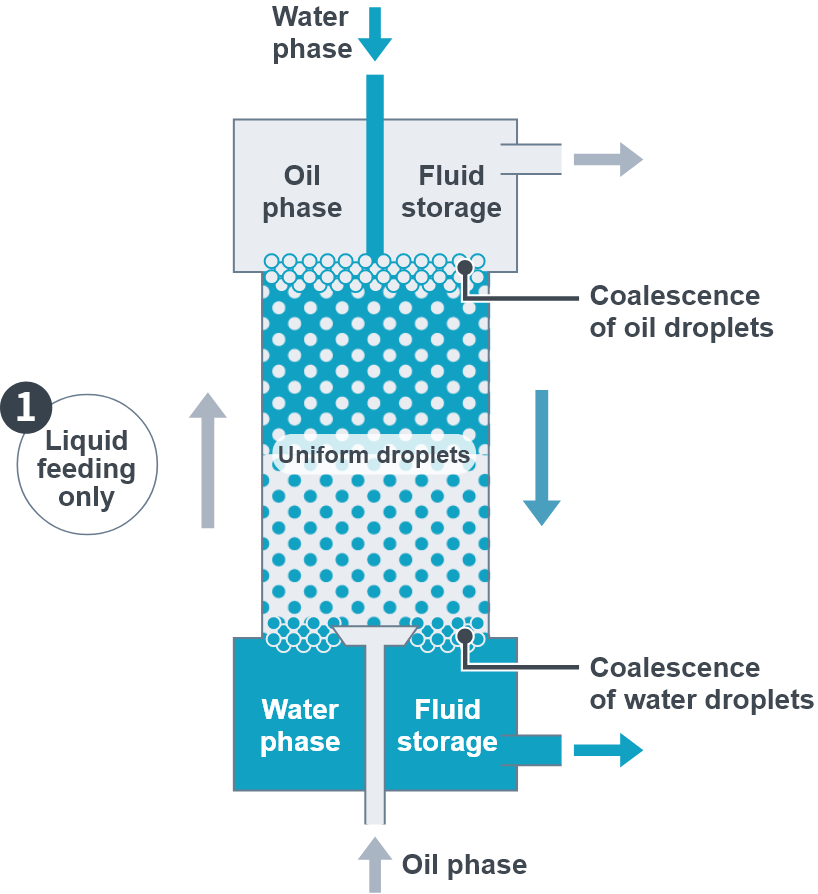

Emulsion Flow is one of the solvent extraction methods developed by JAEA. The revolutionary technology enables ideal solvent extraction in one step “feeding liquid”, in contrast to the conventional solvent extraction technology that requires the three steps of “mixing”, “settling” and “separating” liquid phases.

Mixer-Settler

Emulsion-Flow

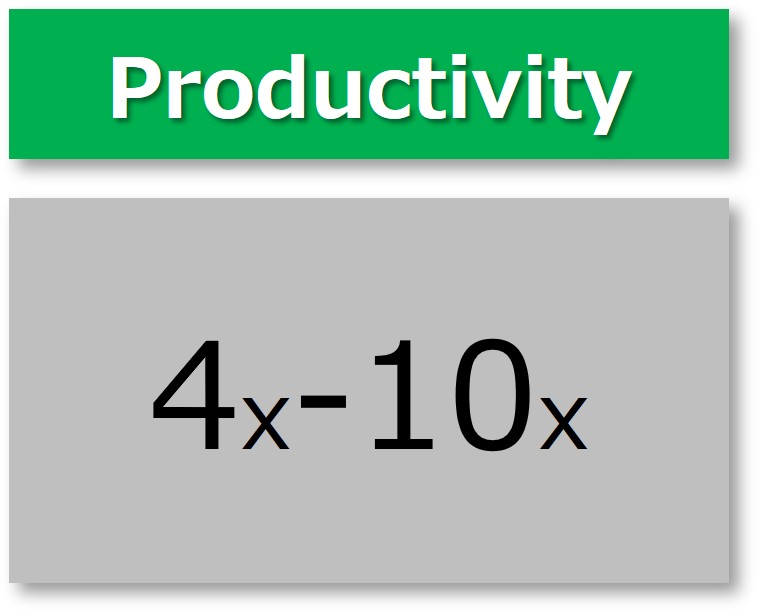

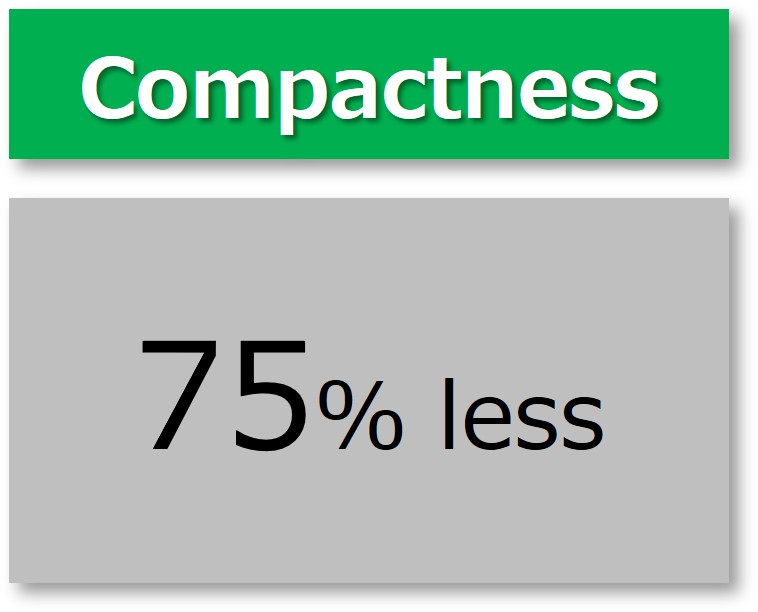

Emulsion Flow, which is highly efficient compared to conventional mixer-settler, realizes downsizing of solvent

extraction plants and enables refining of high-purity rare metals at a low cost.

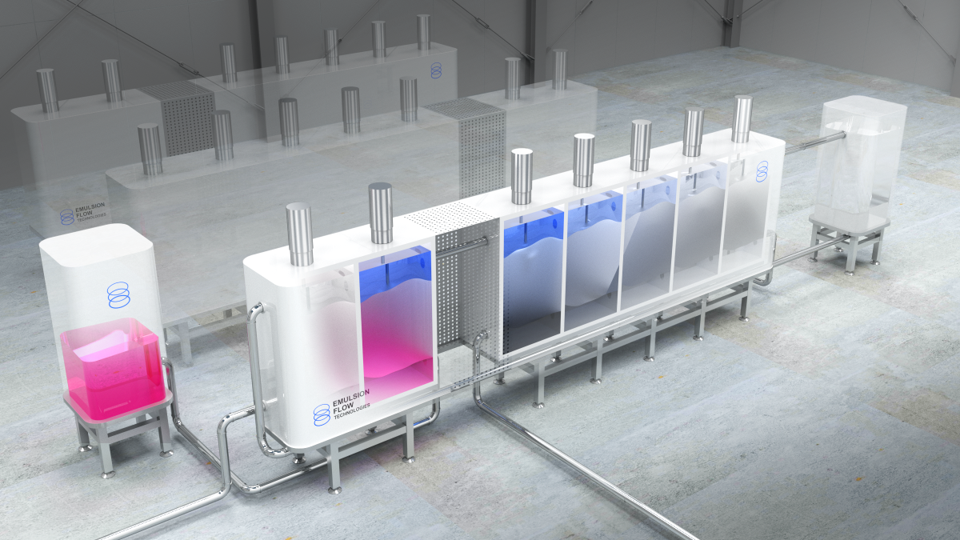

SCALE-UP

We are working on the scale-up development of emulsion flow equipment that enables PFAS removal and LIB recycling at a commercial-scale. We have confirmed that the extraction efficiency remains high regardless of scale, with sufficient performance demonstrated even at the 1000L scale. As a result, we are making steady progress toward full-scale implementation.

Competitive Advantage of Emulsion Flow Plant

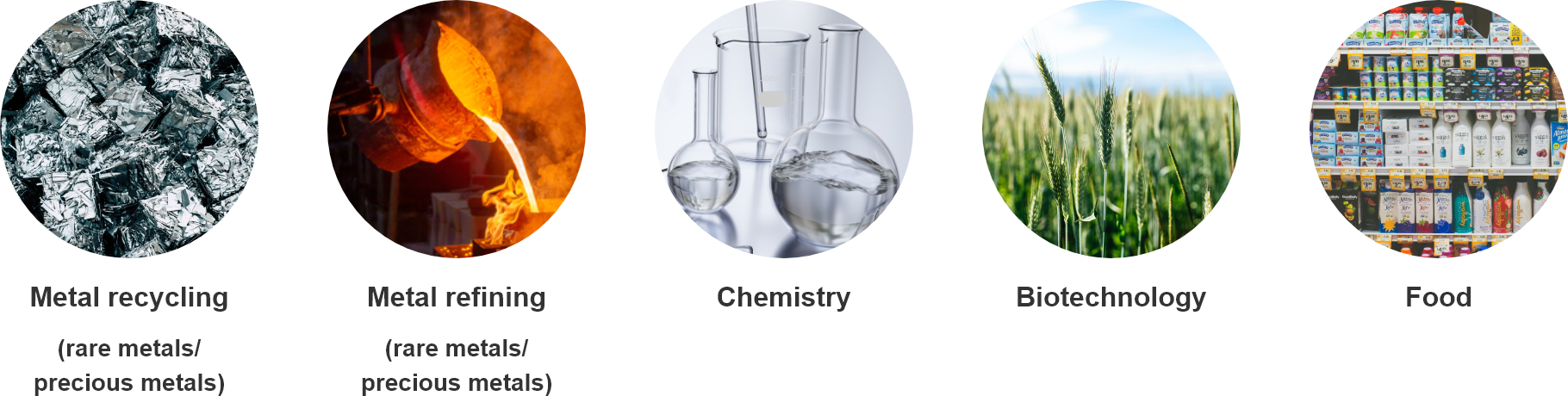

Target Field

The technology can be used not only for rare metal recycling, but also for separation and extraction processes such as separation and refinement, recovery of valuable components, and organic synthesis in metal smelting, chemical, and biotechnologies.